.jpg)

- Slewing Bearings

- High Precision Crossed Roller Bearings

- YRT Precision Rotary Table Bearings

- Full Complement Cylindrical Roller Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Thrust Bearings

- Angular Contact Ball Bearings

- Deep Groove Ball Bearings

- Split Bearings

- Track Roller Bearings

- Backing Bearings

- Self-aligning roller bearings

- Thin Section Bearings

Products list

- Slewing Bearings

- High Precision Crossed Roller Bearings

- YRT Precision Rotary Table Bearings

- Full Complement Cylindrical Roller Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Thrust Bearings

- Angular Contact Ball Bearings

- Deep Groove Ball Bearings

- Split Bearings

- Track Roller Bearings

- Backing Bearings

- Self-aligning roller bearings

- Thin Section Bearings

Contact Us

- Luoyang Nice Bearing Co.,Ltd.

- Address:Lianmeng Road, Jianxi district, Luoyang City,Henan province.

- E-mail:sales@lynicebearing.com

- E-mail:techsupport@lynicebearing.com

- Tel:+86-0379-60689957

- Fax:+86-0379-60689929

- skype:Nettie.Ma

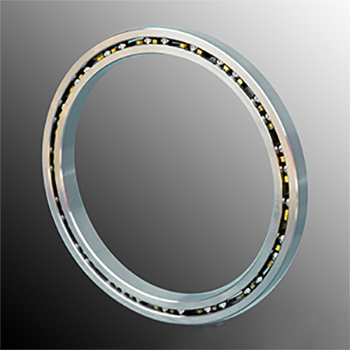

Thin Section Bearings

To learn about thin section bearings

Angular Contact Ball Bearings

Radial Contact Ball Bearings

4-Point Contact Ball Bearings

Thin section bearings|Thin cross section ball bearings involved in radial ball bearings are a family of bearings designed from a single cross section which remains constant as the bore diameter is increased. The thin section bearing family consists of 9 primary cross section sets ranging from 0.1875×0.1875 inch to 1×1 inch and with bore diameter ranging from 1 inch to over 40 inch. The combination of a large bore diameter in proportion to the small cross section makes these parts appear “thin” in contrast to standard ball bearings.

Thin section bearings are made from 52100 chrome steel and 440C stainless steel. They can also be coated with chromium plating.

Some sizes can be configured with seals or shields(specification Nitrile Rubber). Within these families, you can generally choose between open bearings for applications where bearings will not be exposed to damaging particulates and sealed bearings for applications where bearings need to be kept clean and well-lubricated.

Some sizes can be configured with seals or shields(specification Nitrile Rubber). Within these families, you can generally choose between open bearings for applications where bearings will not be exposed to damaging particulates and sealed bearings for applications where bearings need to be kept clean and well-lubricated.

To support various load conditions, thin section bearings are available in three basic types: angular contact (Type A),radial contact (Type C), and four-point contact (Type X), and in a variety of sizes, or series(e.g.,NBKA,NBKB,NBKC,etc.) and interchange with Kaydon KA,Kaydon KB,Kaydon KC,etc.

Thin section bearings are available with various retainer options to space the rolling elements uniformly and prevent contact between them. Retainer types available contain: continuous ring”snap-over pocket”, continuous ring circular pocket, formed wire, PTFE spacers, and spacer ball separators. Different material of separators are available for unusual operating conditions including stainless steel, brass ,aluminum and non-metallics composite such as phenolic laminate, PTFE,PEEK and reinforced nylon.

Thin section bearings featured as saving weight, creating space, reducing friction, increasing design flexibility and providing excellent running accuracy which that is applied for special operation conditions. Especially in the case of medical equipment, airborne optical and robotics, the space and weight requirements of a system are major factors in overall design and manufacturing cost.

Type AAngular Contact Ball Bearings

The type A is also designed for which is featured a circular pocket separator and a 30° contact angular. The main advantage of the type A bearings is that it brings out high axial loads and also bears unidirectional thrust capacity. Thus, the type A bearing also make a good difference in radial or combined radial-thrust applications. The type A bearing should never be used alone to support moment loads or reversing axial loading.

Type CRadial Contact Ball Bearings

The type C radial contact bearing is designed with a single row deep groove ball bearing with the raceway of the inner and outer ring. Due to the way of contract, it would allow them to withstand high loads itself. Although the type C bearing is used mainly in applications with radial loads, it can accept some moderate axial loads, reversing axial loads, and moment loads.

Type X4-Point Contact Ball Bearings

The type X bearing or four-point contact bearing are designed with gothic arch raceways creating 4 contact points between the balls and the raceways. Because of its special designation, the type X bearings would be excellent for moment loading and reversing axial loading. Meanwhile, the type X bearings can be provided for other light loading conditions, but not be recommended in place of the type A or type C bearing for pure radial loads.

▲ The design’s of all these Precision Thin Section Bearings|Thin Cross Section Ball Ball Bearings|Ultra Slim Thin Section Bearings are based on standard structures; LYNBC can design and manufacture many other similar structures in accordance to the special and particular requirements of their customers’. If our customer’s have specific requests then the customer should identify the structure, and mounting dimensions that are required. Please contact the LYNBC Technical Center if you need any assistance in this area.

Contact Us

Luoyang Nice Bearing Co.,Ltd.

- Lianmeng Road, Jianxi district, Luoyang City,Henan province.

- sales@lynicebearing.com

- techsupport@lynicebearing.com

- +86-0379-60689957

- +86-0379-60689929

- Nettie.Ma

Leave a Message

Please leave a message,and we will immediately answer your questions.

Copyright © 2015 Luoyang Nice Bearing Co.,Ltd. All rights Reserved. Privacy Policy Powered by MetInfo